-

Blowing Agent For PVC

-

Blowing Agent For EVA

-

Blowing Agent For PE/PP

-

Blowing Agent For Rubber

-

Other Blowing Agent

CELLCOM -AC Series Azodicamonamide

CELLCOM – AC series are widely used as common chemical blowing agent for foamed plastics and rubbers because of lots of advantage of low toxicity, high decomposition temperature, high expansion ratio and so on. CELLCOM – AC series have diversity in particle size according to customer’s needs.

CELLCOM – SM Series Modified Azodicamonamide

CELLCOM – SM series are designed as modified Azodicarbonamide for application where excellent whiteness, high productivity and lower temperature process are needed.

CELLCOM – OBSH Series p,p-Oxybis benzene sulfonylhydrazide

Unlike with AC and DPT, CELLCOM – OBSH series are white blowing agent having low decomposition temperature, releasing nitrogen gas mainly mainly and widely using for EPDM weatherstrip and high quality PVC wall coverings where need outstanding whiteness.

Property Table of Blowing Agent for PVC

CELLCOM -AC Series

| CELLCOM -AC Series Azodicamonamide | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| Normal | Orange yellow fine powder | 200~205 | 280~300 | PE, PP, PVC, PS, EVA, ABS, Rubber |

| F type | ||||

| DB Type | PVC, Rubber | |||

| MC Type | ||||

| FX Type | Light yellow fine powder | PE, PP, PVC, PS, ABS | ||

| AZO Type | Orange yellow fine powder | X-LDPE, PP | ||

CELLCOM – SM Series

| CELLCOM – SM Series Modified Azodicamonamide | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| CF Type | Light yellow fine powder | 128~167 | 180~210 | EVA, PE, Rubber |

| KL Type | 110~161 | 165~190 | EVA, TPE, PVC | |

| ACF Type | 140~145 | 195~215 | PVC, TPE, Rubber | |

| OAC Type | 137~150 | 150~255` | ||

CELLCOM – OBSH Series

| CELLCOM – OBSH Series p,p-Oxybisbenzenesulfonylhdrazide | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| OBSH Series | White fine powder | 158~164 | 128~140 | EPDM, CR, SBR, PVC, EVA |

CELLCOM – JTR Series Modified Azodicarbonamide

CELLCOM – JTR series as our representative blowing agent in EVA can improve physical properties of EVA sponge.

CELLCOM – AC Series Azodicamonamide

CELLCOM – AC series are widely used as common chemical blowing agent for foamed plastics and rubbers because of lots of advantage of low toxicity, high decomposition temperature, high expansion ratio and so on. CELLCOM – AC series have diversity in particle size according to customer’s needs.

CELLCOM – SM Series Modified Azodicamonamide

CELLCOM – SM series are designed as modified Azodicarbonamide for application where excellent whiteness, high productivity and lower temperature process are needed.

CELLCOM – ACP Series Modified Azodicamonamide

CELLCOM – ACP series are relatively economical grades for manufacturing of cellular rubber, PE and EVA by compression molding.

CELLCOM – OBSH Series p,p-Oxybis benzene sulfonylhydrazide

Unlike with AC and DPT, CELLCOM – OBSH series are white blowing agent having low decomposition temperature, releasing nitrogen gas mainly mainly and widely using for EPDM weatherstrip and high quality PVC wall coverings where need outstanding whiteness.

Property Table of Blowing Agent for EVA

CELLCOM – JTR Series

| CELLCOM – JTR Series Modified Azodicamonamide | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| JTR Type | Light yellow fine powder | 130~157 | 160~180 | EVA, PE, Rubber |

| F | 122~130 | |||

CELLCOM – AC Series

| CELLCOM -AC Series Azodicamonamide | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| Normal | Orange yellow fine powder | 200~205 | 280~300 | PE, PP, PVC, PS, EVA, ABS, Rubber |

| F type | ||||

| DB Type | PVC, Rubber | |||

| MC Type | ||||

| FX Type | Light yellow fine powder | PE, PP, PVC, PS, ABS | ||

| AZO Type | Orange yellow fine powder | X-LDPE, PP | ||

CELLCOM – SM Series

| CELLCOM – SM Series Modified Azodicamonamide | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| CF Type | Light yellow fine powder | 128~167 | 180~210 | EVA, PE, Rubber |

| KL Type | 110~161 | 165~190 | EVA, TPE, PVC | |

| ACF Type | 140~145 | 195~215 | PVC, TPE, Rubber | |

| OAC Type | 137~150 | 150~255` | ||

CELLCOM – ACP Series

| CELLCOM – ACP Series Modified Azodicamonamide | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| ACP Series | Light yellow fine powder | 132~138 | 120~130 | PVC, TPE, Rubber |

CELLCOM – OBSH Series

| CELLCOM – OBSH Series p,p-Oxybisbenzenesulfonylhdrazide | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| OBSH Series | White fine powder | 158~164 | 128~140 | EPDM, CR, SBR, PVC, EVA |

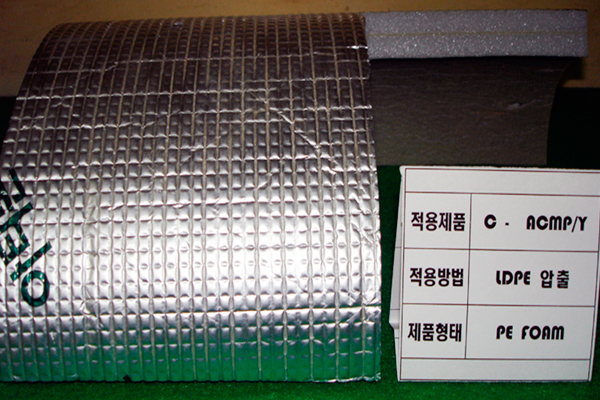

CELLCOM – ACMP Series Specially Azodicarbonamide

CELLCOM – ACMP series are specially designed for chemically & physically cross-linked PE foams.

CELLCOM – AC Series Azodicamonamide

CELLCOM – AC series are widely used as common chemical blowing agent for foamed plastics and rubbers because of lots of advantage of low toxicity, high decomposition temperature, high expansion ratio and so on. CELLCOM – AC series have diversity in particle size according to customer’s needs.

Property Table of Blowing Agent for PE & PP

CELLCOM – ACMP Series

| CELLCOM – ACMP Series Specially Azodicamonamide | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| ACOP type | Orange yellow fine powder | 188~202 | 280~290 | X-LDPE |

| ACMP type | 196~200 | 270~290 | ||

CELLCOM – AC Series

| CELLCOM -AC Series Azodicamonamide | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| Normal | Orange yellow fine powder | 200~205 | 280~300 | PE, PP, PVC, PS, EVA, ABS, Rubber |

| F type | ||||

| DB Type | PVC, Rubber | |||

| MC Type | ||||

| FX Type | Light yellow fine powder | PE, PP, PVC, PS, ABS | ||

| AZO Type | Orange yellow fine powder | X-LDPE, PP | ||

CELLCOM – OBSH Series p,p-Oxybis benzene sulfonylhydrazide

CELLCOM – OBSH series are white blowing agent having low decomposition temperature and no ammonia gas evolved, different with AC, and widely used for the manufacture of EPDM weatherstrip and special application like CR diving suits.

CELLCOM – TSH Series p-Toluene sulfonyl hydrazied

CELLCOM – TSH series are white blowing agent having low decomposition temperature as like as OBSH and suitable for rubber vulcanization sponge.

CELLCOM – ACP Series Modified Azodicarbonamide

CELLCOM – ACP series are relatively economical grades for manufacturing of cellular rubber, PE and EVA by compression molding.

CELLCOM – AC Series Azodicamonamide

CELLCOM – AC series are widely used as common chemical blowing agent for foamed plastics and rubbers because of lots of advantage of low toxicity, high decomposition temperature, high expansion ratio and so on. CELLCOM – AC series have diversity in particle size according to customer’s needs.

CELLCOM – SM Series Modified Azodicarbonamide

CELLCOM – SM series are designed as modified Azodicarbonamide for application where excellent whiteness, high productivity and lower temperature process are needed.

Property Table of Blowing Agent for Rubbers

CELLCOM – OBSH Series

| CELLCOM – OBSH Series p,p-Oxybisbenzenesulfonylhdrazide | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| OBSH Series | White fine powder | 158~164 | 128~140 | EPDM, CR, SBR, PVC, EVA |

CELLCOM – TSH Series

| CELLCOM – TSH Series p-Toluenesulfonylhydrazied | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| TSH Series | White fine powder | 148~154 | 120~130 | Rubber (NR, SBR, IIR) |

CELLCOM – ACP Series

| CELLCOM – ACP Series Modified Azodicamonamide | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| ACP Series | Light yellow fine powder | 132~138 | 120~130 | PVC, TPE, Rubber |

CELLCOM – AC Series

| CELLCOM -AC Series Azodicamonamide | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| Normal | Orange yellow fine powder | 200~205 | 280~300 | PE, PP, PVC, PS, EVA, ABS, Rubber |

| F type | ||||

| DB Type | PVC, Rubber | |||

| MC Type | ||||

| FX Type | Light yellow fine powder | PE, PP, PVC, PS, ABS | ||

| AZO Type | Orange yellow fine powder | X-LDPE, PP | ||

CELLCOM – SM Series

| CELLCOM – SM Series Modified Azodicamonamide | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| CF Type | Light yellow fine powder | 128~167 | 180~210 | EVA, PE, Rubber |

| KL Type | 110~161 | 165~190 | EVA, TPE, PVC | |

| ACF Type | 140~145 | 195~215 | PVC, TPE, Rubber | |

| OAC Type | 137~150 | 150~255` | ||

CELLCOM – TSS Series p-Toluenesulfonyl semicarbazide

CELLCOM – TSS series as high temperature decomposition blowing agents are useful for foaming of high temperature engineering plastics (ABS, PS, PP and so on) and especially have an advantage that can control processing temperatures for rigid extrusion process.

CELLCOM – 5PT 5-Phenyltetrazole

CELLCOM – 5PT as a ultra high temperature decomposition blowing agent is suitable for foaming of extra high temperature engineering plastics (PC, Nylon, PET and so on).

KYCEROL Series Modified Sodium Bicarbonate

KYCEROL series as inorganic chemical blowing agents have endo-thermic decomposition property, non-toxicity and non-odor, and excellent flow ability during process and are used for preventation of shrinkage for injected mold and manufacturing of cap seals and so on.

Property Table of Blowing Agent for others

CELLCOM – TSS Series

| CELLCOM – TSS Series p-Toluenesulfonylsemicarbazide | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| TSS Series | White fine powder | 229~235 | 150~160 | HDPE, PP, PVC, ABS, HIPS |

CELLCOM – 5PT

| CELLCOM – 5PT Series 5-Phenyltetrazole | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| 5PT | White fine powder | 234~245 | 180 up | PC, Nylon, PET, ABS, Fluoro Plastics |

KYCEROL Series

| KYCEROL Series Modified Sodiumbicarbonate | ||||

|---|---|---|---|---|

| Classfication | Externals | Decomposition Temperature (℃) | Gas Quantity (ml/gr) | Mainly Applied to resin |

| KYCEROL Series | White fine powder | 150~190 | 115~125 | PE, PP, PVC, PS, ABS, HIPS |